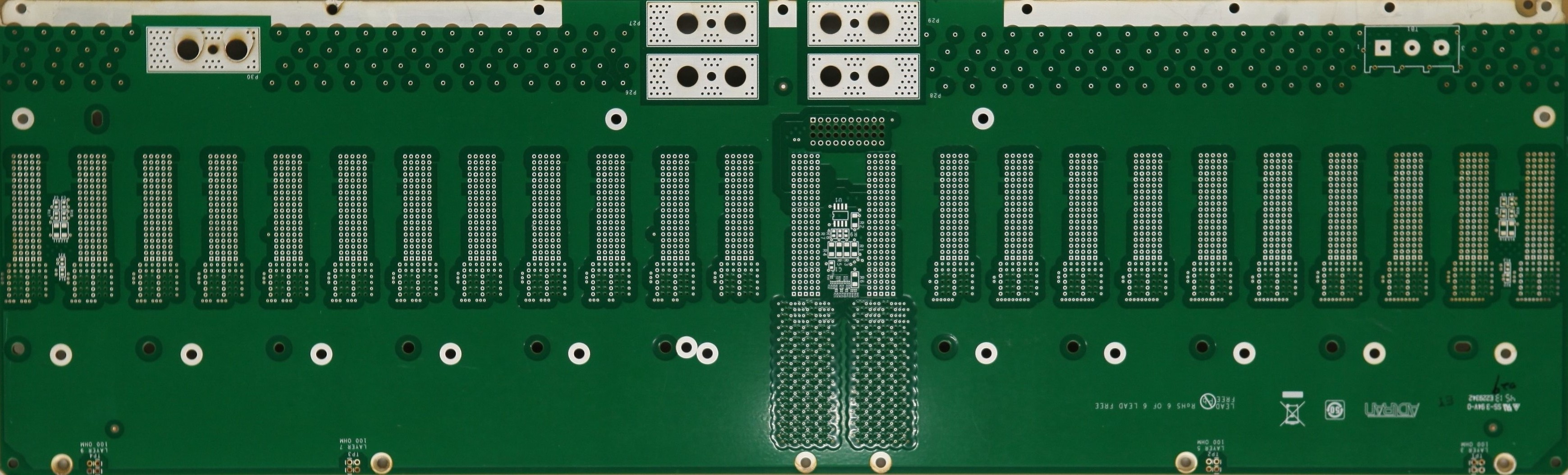

Backplanes or "back panels" are typically higher layer count than standard PCB's, often 20 to 40 layers or more. They are large and thick, with rows of press-fit holes for high speed connectors. The connectors allow daughter-cards or line-cards to be plugged in and swapped out easily. Backplanes may be passive or active, with passive ones lacking on-board processing and memory devices. In some cases, line-cards may plug in from both sides, in which case the boards are called Midplanes.

The applications for backplanes push these boards to extremely high speeds (>100 GHz). The reliability of data transmission is critical to ensure 0 packet loss. Signal integrity (SI) therefore becomes very critical in backplane systems.

The base materials used in backplanes are usually very low loss, and may also use low Dk glass and HVLP copper foils. Rotation of the image on the production panel or use of zig-zag routing may also be used to minimize weave effect and skew.

Backdrill is utilized to remove the unused portion of PTH's (stubs) which cause signal reflection and degrade SI. Our state-of-the-art backdrill systems have panel mapping capability to ensure depth consistency and repeatability. Sunshine can perform backdrill from both sides to various depths. Blind and buried vias may also be used to minimize the length of the barrels to improve SI.

Sunshine Global Circuits have the expertise and experience to build high-layer count backplanes. We offer industry-leading ultra low loss materials, high precision backdrill process, tight tolerance impedance control, and the know-how to ensure your product meets SI requirements.